Stationary Seal Food Grade Rubber Silicone O Ring

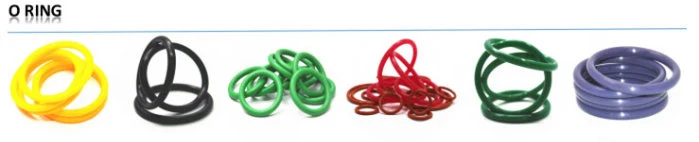

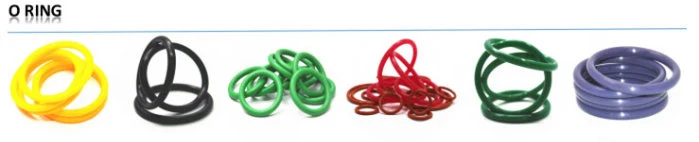

Products Show:

Basic Info.

Silicone is a kind of most widely used material for o ring seals. its' fuction as below:

We carry extensive stock of O-rings in NBR, HNBR, Viton, EPDM and Silicone as well as special materials and grades for demanding applications in the Petrochemical, Gas, Water and Food industries to name but a few. Standard sizes stocked comply with AS568, DIN 3771, BS1806, BS4518, or ISO3601 specifications.

In designing an O-ring Seal, it is best to determine the O-ring compound first, as the selected compound may have significant influence on gland design parameters. Essentially, the application determines the rubber compound; The primary factor being the fluid to be sealed. The elastomer however, must also resist extrusion when exposed to the maximum anticipated system pressure and be capable of maintaining good physical properties through the full temperature range expected. In dynamic applications, the selected material must also have the toughness and abrasion resistance so important in reciprocating and rotary seals. Essentially, the application determines the rubber compound; The primary factor being the fluid to be sealed. The elastomer however, must also resist extrusion when exposed to the maximum anticipated system pressure and be capable of maintaining good physical properties through the full temperature range expected. In dynamic applications, the selected material must also have the toughness and abrasion resistance so important in reciprocating and rotary seals.

FAQ:

1,Are you manufacture or trading company ?

We are manufacture, we have two factories, one located in Shangrao City, Jiangxi Province, one in Dongguan City, Guangdong Province

2,Can I get samples from you ?

Of course, you can. If the samples you need we have in stock, you can get them for free,

only need to pay for the express cost.

3,What's the term of payment ?

Amount < US$2000, 100% paid in advance by paypal or T/T;

Amount >= US$2000, 30% paid in advance, 70% balance before shipment by T/T.

4,Can you produce OEM products ?

Yes, we can produce products by your drawing or samples.

5,What's your MOQ ?

If we have the products in stock , the quantity by your requirement, If we don't have them in stock:

NBR, SIL, SBR, EPDM, NR: 100 US$; PU, HNBR, FKM: 150 US$

Products Show:

Basic Info.

Silicone is a kind of most widely used material for o ring seals. its' fuction as below:

| Material | SIL(Silicone Rubber) |

| Advantage | 1,Excellent Rebound Resistance |

| 2,Excellent Oxygen and Ozone Resistance | |

| 3,Excellent Weathering and Heat Resistance | |

| 4,Excellent Heat and Low Temperature Resistance | |

| 5,Good heat insulation and heat dissipation. | |

| 6,Good electrical insulation | |

| Disadvantage | 1,Poor Aliphatic-solvent Resistance |

| 2,Poor Alkaline Resistance | |

| Temperature | -40ºC-220ºC, -100ºC-250ºC(special formula) |

| Application | 1,the household appliances industry seal or rubber parts, such as electric kettle, electric irons, microwave oven rubber parts. |

| 2,The electronics industry seal or rubber parts, such as mobile phone keys, shock pad DVD, cable joint seal etc. | |

| 3,Contact with the human body on various types of products on the seal, such as water bottles, water dispensers |

We carry extensive stock of O-rings in NBR, HNBR, Viton, EPDM and Silicone as well as special materials and grades for demanding applications in the Petrochemical, Gas, Water and Food industries to name but a few. Standard sizes stocked comply with AS568, DIN 3771, BS1806, BS4518, or ISO3601 specifications.

In designing an O-ring Seal, it is best to determine the O-ring compound first, as the selected compound may have significant influence on gland design parameters. Essentially, the application determines the rubber compound; The primary factor being the fluid to be sealed. The elastomer however, must also resist extrusion when exposed to the maximum anticipated system pressure and be capable of maintaining good physical properties through the full temperature range expected. In dynamic applications, the selected material must also have the toughness and abrasion resistance so important in reciprocating and rotary seals. Essentially, the application determines the rubber compound; The primary factor being the fluid to be sealed. The elastomer however, must also resist extrusion when exposed to the maximum anticipated system pressure and be capable of maintaining good physical properties through the full temperature range expected. In dynamic applications, the selected material must also have the toughness and abrasion resistance so important in reciprocating and rotary seals.

FAQ:

1,Are you manufacture or trading company ?

We are manufacture, we have two factories, one located in Shangrao City, Jiangxi Province, one in Dongguan City, Guangdong Province

2,Can I get samples from you ?

Of course, you can. If the samples you need we have in stock, you can get them for free,

only need to pay for the express cost.

3,What's the term of payment ?

Amount < US$2000, 100% paid in advance by paypal or T/T;

Amount >= US$2000, 30% paid in advance, 70% balance before shipment by T/T.

4,Can you produce OEM products ?

Yes, we can produce products by your drawing or samples.

5,What's your MOQ ?

If we have the products in stock , the quantity by your requirement, If we don't have them in stock:

NBR, SIL, SBR, EPDM, NR: 100 US$; PU, HNBR, FKM: 150 US$