The wrap ring (PTFE wrap) combines the elasticity and sealing properties of the rubber with the chemical resistance of Teflon. It is made of a silicone or Viton rubber (fluorine rubber) and a relatively thin core Teflon FEP (Teflon) or Teflon PFA (Soluble Polytetrafluoroethylene), this rubber Teflon seal has excellent sealing properties.

Rubber O-ring is easy to wear, chemical resistance and resistance to gas permeability is poor, pure O-ring high hardness can be compressed but poor flexibility. Teflon FEP / Teflon PFA O-rings have excellent resistance to dissolution and chemical stability (unless they are attacked by alkali metals, fluorine and some halides at high temperatures) have good elasticity near the rubber O-ring , FEP / Teflon PFA has a very small coefficient of friction (only 0.1 to 0.2), and has excellent resistance to gas permeability, these properties make the ring ring can be truly applied in harsh environments.

Therefore, the PTFE coated O-ring, instead of expensive perfluoro rubber O-ring.

Features:

The combination of the Teflon FEP / Teflon PFA overcoat and the rubber inner core makes the uniformity of the wrap ring seal uniform, and the elasticity and compression of the points on the seal are uniform and, after continuous pressure The role can be repeated under the use of installation. With the increase of medium pressure, the whole seal is compressed. The wrapping ring is like a high-viscosity liquid that transfers the pressure acting on it in all directions without any reduction.

Material:

Teflon FEP and Teflon PFA are very similar in nature, but Teflon PFA is more resistant to high temperatures than Teflon FEP

Applicable temperature range

Teflon FEP shell: -60 ºC ~ 205 ºC can be used in the 260 ºC high temperature for a short time

Teflon PFA Enclosure: -60 ºC ~ 260 ºC can be used at 300 ºC high temperature for a short time

Solid wrap ring seals are preferred, plenty of applications with static seals and dynamic seals. Hollow silicone rubber wrap ring wire diameter generally do larger, used in static seal, its hardness and anti-compression than the core envelope ring low.

Compressibility:

The presence of the FEP overcoat gives the cladding ring a good resistance to hardenability and resistance to brittleness while the silicone rubber or Viton rubber core allows the seal to maintain good elasticity at a high temperature of 205 ° C. Kalrez rubber (perfluoroether rubber), Viton rubber and covered with FEP covered ring three O-ring in the compression device in the sealing performance comparison shown as follows: test results show that the silicone rubber or Viton rubber physical Performance and Teflon FEP / Teflon PFA combined with the chemical properties of the formation of the ring ring to maintain the rubber properties while maintaining good compression resistance. The construction of the wrap ring seal is subject to strict quality control, and the Teflon FEP polymer is completely wrapped around the rubber inner core by a special process, and it is ensured that the O-ring has the required standard tolerances. The information used indicates that we have a good quality commitment to the covered loop product, which is based on performance testing and rigorous control to ensure customer satisfaction and safe use of this product. The covered ring seal has unparalleled tightness and long life compared to any other rubber or pure Teflon O-rings, especially in harsh media.

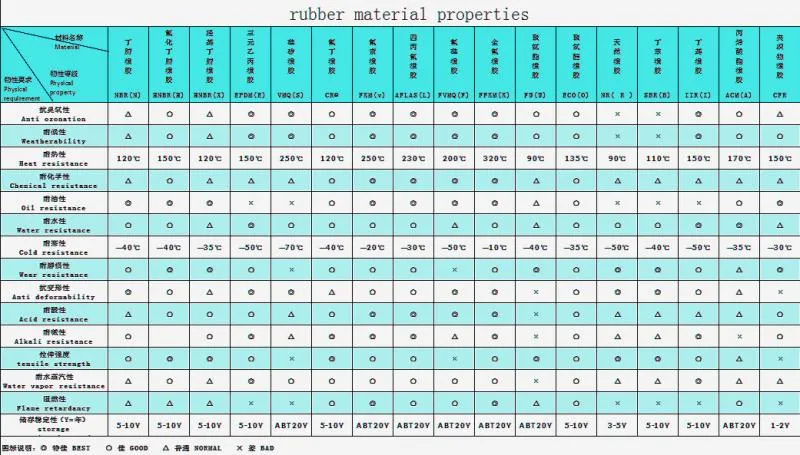

Chemical resistance

The Teflon FEP / Teflon PFA is an essential component of the cladding ring, which has excellent resistance to chemical attack. At normal use temperatures, Teflon FEP / Teflon PFA is attacked by only a few chemicals, In this case only chemicals that are not compatible with it, such as some metal base, fluoride and some halides, are not compatible with Teflon FEP / Teflon PFA.

Some high concentrations of chemicals react with Teflon FEP (recommended limit temperature of 204 ° C / 400 ° F) / Teflon PFA (recommended limit temperature of 260 ° C / 500 ° F). At high temperatures, Teflon FEP / Teflon PFA (89 H6), aluminum chloride, ammonia (NH3) and some amino acids (NH2) and imino groups (R = NH) are eroded by 80% NaOH and KOH, organic compounds such as KOH, metal hydrides. At temperatures up to 250 ° C / 480 °, it will also be attacked by a chronic oxidation of 70% nitric acid.

If used in these extreme conditions, the product must be specially tested. In addition to these chemicals mentioned, the wraps are generally chemically inert to other chemicals.

Key Benefits:

1, prominent chemical resistance, almost applicable to all chemical media

2, excellent corrosion resistance

3, the temperature range for a wide range

4, good compression resistance

5, anti-friction

6, good resistance to swelling

7, high pressure

8, excellent sealing durability, long service life

use:

1, pump and valve 2, reaction vessel 3, mechanical seal 4, filter 5, pressure vessel 6, heat exchanger 7, boiler 8, pipe flange 9, gas compressor

Application Industry:

1, chemical process 2, aircraft manufacturing 3, the pharmaceutical industry 4, oil and chemical transport 5, refining 6, film industry 7, refrigeration engineering 8, food processing industry 9, paper industry 10, dye manufacturing 11, paint spray

Installation instructions for covered ring seals:

1, the installation or through the cover ring ring parts of the requirements of smooth, burr, groove and sharp corners, the hole of the profile should reach 20 milli-inch, the shaft of the profile should reach 10 milli-inch.

2, with a clean light oil or grease smear covered with grease ring ring surface and the contact with the relevant parts.

3, if the wrap ring seal is installed on the shaft more difficult, it can be immersed in hot water for a few minutes to expand, this softened and inflated O-ring installation easier. In the heat when the installation of this O-ring, and so cool down its size and restore to the original.

4, do not be too intense to wrap the O-ring, otherwise it will cause Teflon folds and affect the use.

The required compression of the wrap ring seal is as follows:

Static seal state: 15% -20%

Dynamic seal state: 10% -12%

Pneumatic state: 7% -8%

Cross section:

O-shaped cross-section of the ring ring is a standard product, of course, can also be made square and rectangular cross-section of the ring ring, this seal applied to the larger sealing surface and can withstand greater positive pressure, and its The mounting dimensions are the same as those of the O-section, but it requires a lower amount of compression.

O-shaped cross-section of the cover ring seal application is very common, square or rectangular cross-section of the ring ring is usually applied in some specific circumstances, before ordering, please contact our company or distributor and consultation.

The cross-section of the covered ring seal is designed to conform to the nominal cover of the nominal aperture, which is called a rectangular ring with a rectangular seal that covers the Teflon FEP / PFA with different specifications and inner diameter The size series is as complete as the wrapping circle