Product details

| Item name: | Oil Seal | ||

| Meterial: | NBR | ||

| Application: | Engine, Transmission, Rear Axle,gearbox,booster pump. | ||

| Speed: | Speed Mechanical Seal | ||

| lip: | Double lips and single lip are available | ||

| Shape: | O Type | ||

| Color: | Black, brown or as you required | ||

| Pressure: | Pressure type | ||

| Working Medium: | Hydraulic Oil, Water and Dust | ||

| Payment terms: | L/C or T/T | ||

| Trademark: | ODM, OEM | ||

| Performance: | High temperature resistance,Good oil resistance | ||

| Standard: | Nonstandard / Standard | ||

| Hardness: | 30-100 | ||

| Transport package: | Carton or as Your Required | ||

| Factory visit: | Available | ||

| Company Type | Manufacturer/Factory & Trading Company | ||

| Origin: | China(mainland) | ||

| Hscode: | 4016931000 | ||

| Supply | 500000 per/month | ||

Basic Components

Oil Seals

Also described as a rotary oil seal, shaft seal or lip seal. This seal can be supplied in the following materials:

NBR FPM FKM VITON SILICONE HNBR ACM NR EPDM.

The main function of this type of seal is to exclude the ingress of dirt, dust, water or any other extraneous substances whilst maintaining lubricant for the seal lip and protecting rotating bearings.

Temperature: -50°C -120°C Depending On Rubber Material

Pressure: Up to 0.03 MPa

Reciprocation Speed: 0-20m/S

Medias: mineral oils, water, lubricating grease

Specification: 6-13000mm

Hardness: 30-100

Testing Equipments

1,Hardness testing: hardness testing of various materials to ensure product hardness to meet customer requirements.

2,Tensile machine: according to the material property requirements test tensile force, according to the standard through the test.

3,Microscopic examination: sampling rate of 20%, oil seal surface is fine cracks, there is scrap, no pass; if the sampling failure rate of 3% and above, the whole batch of full inspection, to ensure quality.

4,Aging box: aging of the material, the temperature of 200 degrees and above, aging phenomenon, then scrapped.

5,Vulcanizing apparatus: test the quality of the glue material, the value is within the standard range, and then pass the test according to the standard.

Certification

We have passed ROHS , ISO9001:2008 quality system certification.

Packaging & Shipping

Packing:

| Size | Official size |

| Packing | A roll of 10, a bundle of 100, and finally put into the packing box |

Shipping:

| Delivery Time: | 5-7 days after payment |

| Payment Terms: | 100%TT advance payment for LC order |

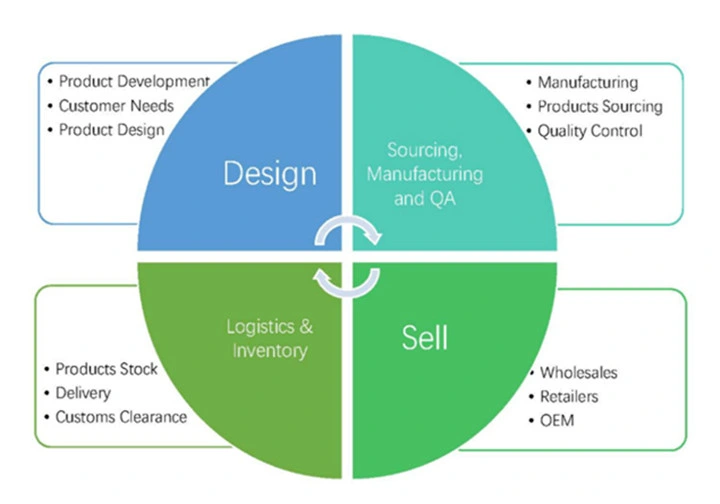

Our Service

As a professional manufacturer of rubber sealing products for 34 years, we offer various kinds oil seals, such as TC, TB, TA, SC, SB, SA, VC, VB, VA, KC, KB, KA, DC, and DB, also can customized based on your specific demand; Material including NBR, SILICONE, VITON,HNBR, CR, PTFE, EPDM, etc for your better choice.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally 3-7 days for standard sealing products; and 15-20 days for big order and custom non-standard products.

Q: Do you provide free samples?

A: Yes, we offer free sample while customer need pay for the freight charge.

Q: Which Payment way is workable?

A: Irrevocable L/C, Cash, PayPal, Credit card and T/T money transfers.

B: 30% T/T deposit in advance, 70% balance before shipment after presentation of ready cargo.

C: L/C ( Irrevocable LC at sight: Order amount over USD10,000)

Q: What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Q: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.

Q: Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.

Q: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, VITON(FKM), NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.